News

Some Tips You May Dont Know About Tungsten Carbide Buttons For Rock Drill Bit

In addition to the choice of tungsten carbide button grade, selecting the right button type and face design is very important for the rock drilling efficiency, also it will have a direct impact on the hole effect and vertical degree. Combined with our production and sales experience, Jinzen Drilling have summarized small tips for reference.

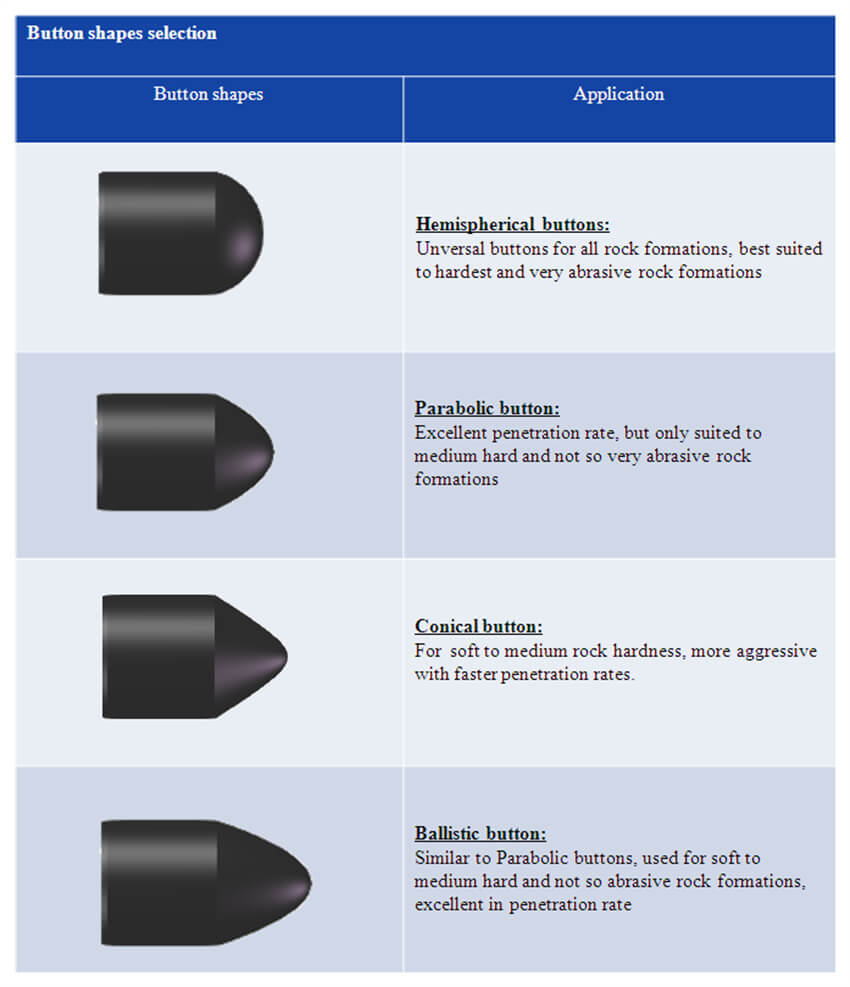

How to choose the bit button type

Button type | Spherical button | Universal button Wearing resistance good Best suited to hard ground 27,000~48,000 PSI (180 to 320 Mpa) Abrasive to very abrasive |

Hemispherical button | Universal button Wearing resistance good Best suited to hard ground 25,000~45,000 PSI (170 to 300 Mpa) Abrasive to very abrasive | |

Parabolic button | Universal button Fast penetration Best suited to medium to hard rock 15,000~25,000 PSI (100 to 170 Mpa) Midly abrasive ground | |

Conical button | Fast penetration Best suited to smaller diameter bits Suited for all non-abrasive ground types | |

Ballistic button | Fast penetration Best suited to soft rock 10,000~20,000 PSI (70 to 140 MPa) Nonabrasive ground |

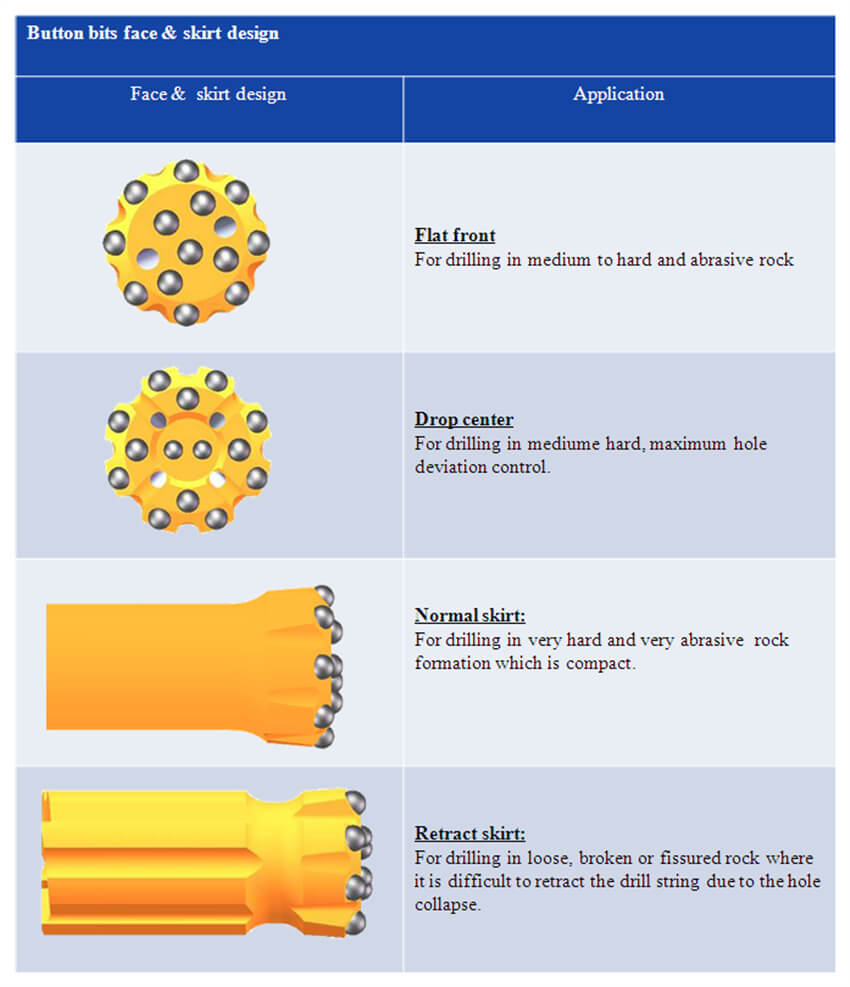

How to select the bit face

Face Type | Flat face | General purpose bit Suited for medium to hard rock |

Drop center | Straight hole application Suited for medium to hard rock | |

New drop center | Straight hole application Suited for medium to hard rock |

Categories

Contact Us

- +86-1583 8088 573

- jinzhendrills@gmail.com

- 1583 8088 573

- +86-1583 8088 573

售前客服

售前客服